Most electronics factory purchasers have been confused about the price of PCBs. even some people with many years of experience in PCB procurement may not fully understand the original reason. In fact, the PCB price is composed of the following factors:

First, the prices are different due to different materials used in the PCB.

Taking ordinary double layers pcb as an example, the laminate varies from FR-4, CEM-3, etc. with thickness ranges from 0.2mm to 3.6mm. The thickness of copper varies from 0.5Oz to 6Oz, all of which caused a huge price difference. The soldermask ink prices also different from normal thermosetting ink material and photosensitive green ink material.

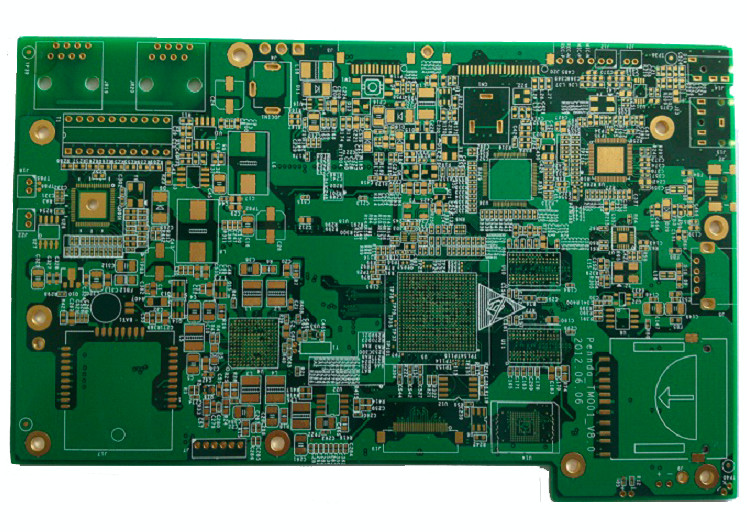

Second, the prices are different due to different production processes.

Different production processeses result in different costs. Such as gold-plated board and tin-plated board, the shape of the routing and punching, the use of silk screen lines and dry film lines will form different costs, resulting in price diversity.

Third, the prices are different due to complexity and density.

PCB will be different cost even if materials and process are the same, but with different complexity and density. For example, if there are 1000 holes on both circuit boards, the hole diameter of one board is larger than 0.6mm and the hole diameter of the other board is less than 0.6mm, which will form different drilling costs. If two circuit boards are same in other requests, but the line width is different also results in different cost, such as one board width is larger than 0.2mm, while the other one with is less than 0.2mm. Because boards width less than 0.2mm have higher defective rate, which means the production cost is higher than normal.

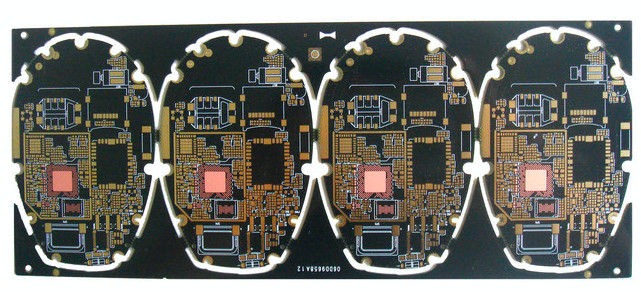

Fourth, the prices are different because of various customer requirements.

The customer requirements will directly affect the non-defective rate in production. Such as one board accords to IPC-A-600E class1 requires 98% pass rate, while accords to class3 requires only have a 90% pass rate, causing different costs for the factory and finally lead to changes in product prices.

Post time: Jun-25-2022