Superior quality, product reliability and product performance are critical to maximizing brand value and market share. Pandawill is fully committed to providing technical excellence and the highest quality service in the field of electronic assembly. Our goal is to manufacture and deliver defect-free products.

Our Quality Management System, and a series of procedures, processes and workflows, are familiar to all of our employees and are an integrated and focused part of our operations. At Pandawill, we emphasize the importance of eliminating waste and lean manufacturing techniques for efficient and most importantly more reliable and conscious manufacturing processes.

Implementing ISO9001:2008 and ISO14001:2004 certifications, we are committed to maintaining and improving our operations in accordance with industry best practices.

Inspection and Testing Including:

• Basic Quality Test: visual inspection.

• SPI check the solder paste deposits in the Printed Circuit Board (PCB) manufacturing process

• X-ray Inspection: tests for BGAs, QFN and bare PCBs.

• AOI Checks: tests for solder paste, 0201 components, missing components and polarity.

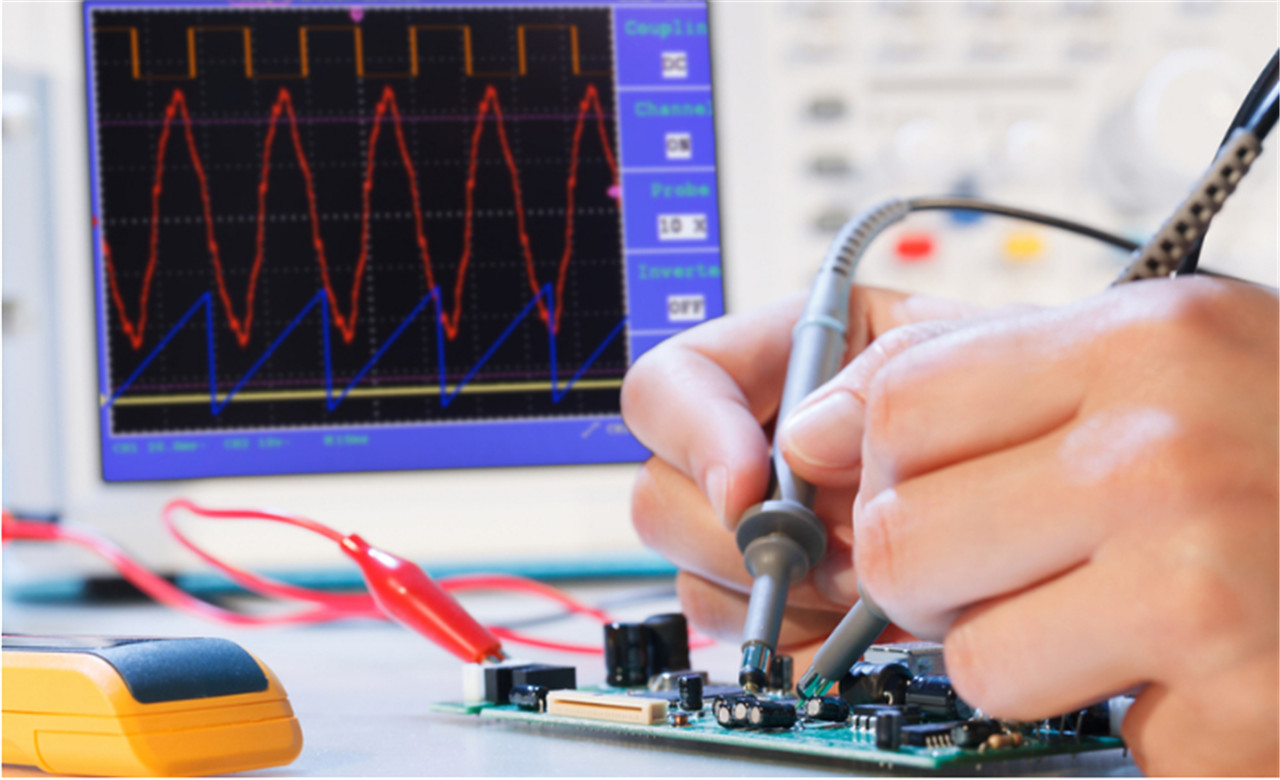

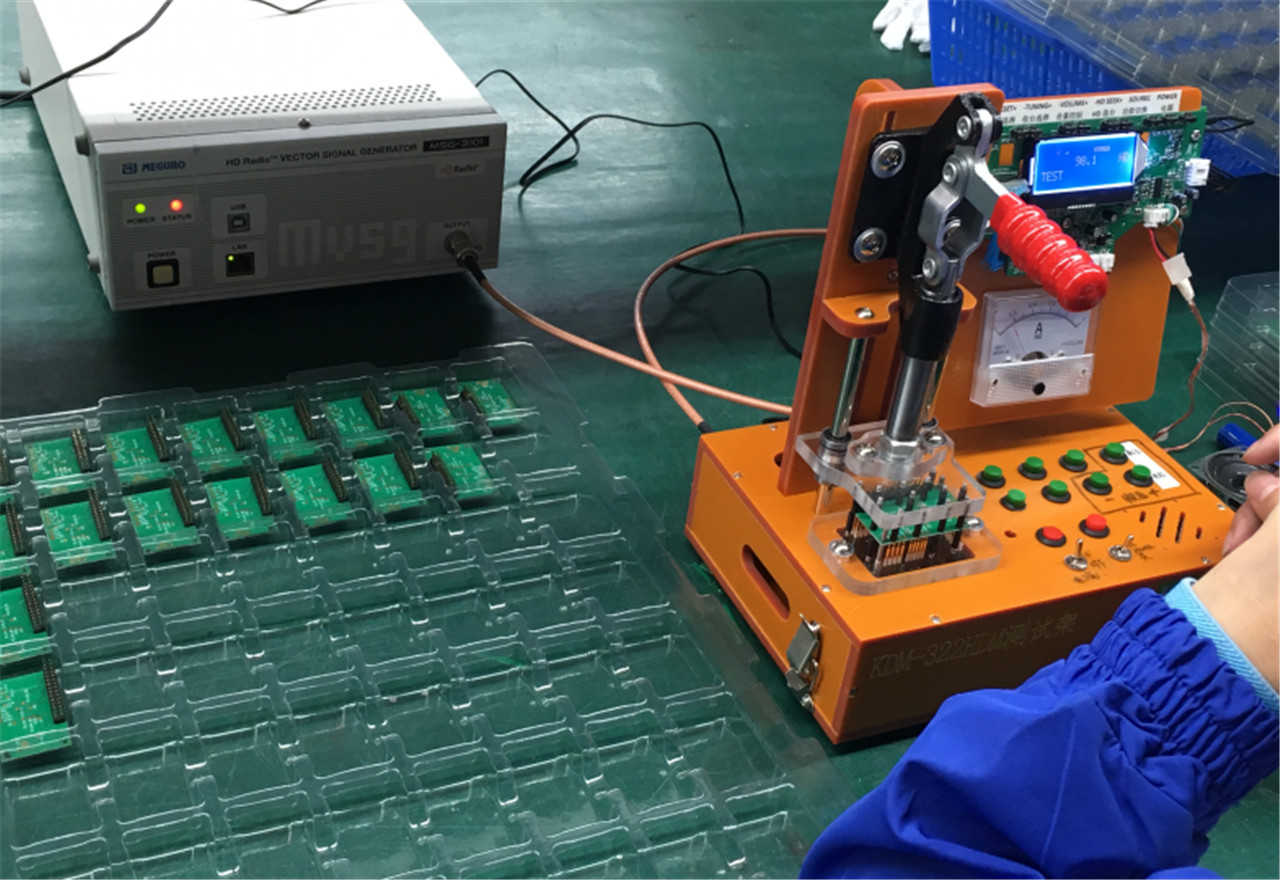

• In-Circuit Test: efficient testing for a wide range of assembly and component defects.

• Functional test: according to the customer’s testing procedures.